Strength Weld

Advanced Tube-End Welding Techniques for Air-Cooled Heat Exchangers: Strength Weld and Roller Expansion

ref: https://europepmc.org/article/pmc/pmc8746155

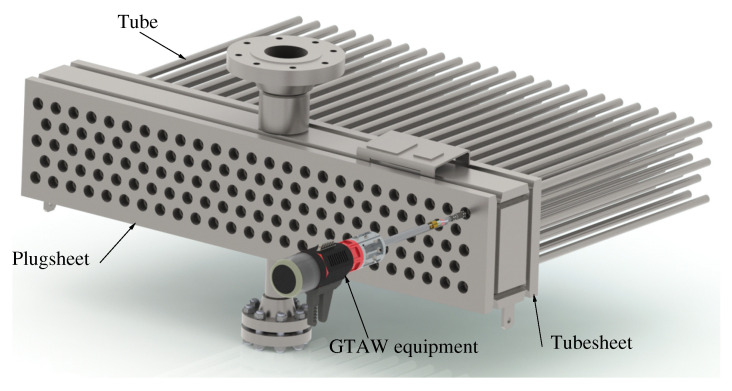

Introduction to Air-Cooled Heat Exchangers and Tube-End Welding (Strength Weld)

- Briefly introduce air-cooled heat exchangers and their significance in industries such as oil & gas, petrochemicals, power generation, and heavy industry.

- Explain the role of tube-end welding in ensuring the integrity, safety, and efficiency of these heat exchangers.

- Mention the importance of specialized techniques like Strength Weld and Roller Expansion for handling high-pressure and high-temperature applications.

Why Tube-End Welding is Essential in Air-Cooled Heat Exchangers

(Strength Weld)

- Describe the critical function of tube ends in heat exchangers, including their role in withstanding operational stress and preventing leaks.

- Discuss how improper tube-end welding can lead to performance issues, increased maintenance, or even system failure in air-cooled heat exchangers.

- Emphasize why industries with stringent safety and performance standards require experienced teams and advanced tools to meet these demands.

Overview of Strength Weld and Roller Expansion

-

Strength Weld:

- Explain the Strength Weld process as a fusion weld that securely bonds the tube to the tubesheet, providing a high-strength joint.

- Mention how this method offers a strong, leak-resistant seal, making it highly reliable for high-stress and high-temperature environments.

- Detail the technical skill required to achieve a precise Strength Weld, as well as the advanced welding equipment needed for consistent results.

-

Roller Expansion:

- Describe Roller Expansion as a mechanical expansion process that creates a tight fit between the tube and the tubesheet without requiring additional material.

- Discuss how Roller Expansion enhances the weld by preventing tube movement, improving resistance to vibration and pressure changes.

- Explain that Roller Expansion is an ideal complement to Strength Weld, providing an extra layer of stability and preventing long-term loosening or leaks.

Advantages of Combining Strength Weld and Roller Expansion

(Strength Weld)

- Enhanced Durability and Stability:

- Detail how the combination of welding and expansion provides a double layer of strength and stability, protecting the tube ends from loosening due to vibration, pressure surges, or temperature fluctuations.

- Superior Leak Prevention:

- Describe how combining these methods creates a highly reliable seal that prevents leaks, even in systems under constant high pressure.

- Reduced Maintenance Costs:

- Explain how the increased durability and leak prevention can reduce maintenance needs and downtime, contributing to overall cost savings.

- Enhanced Safety:

- Emphasize that the reliability of this method makes it ideal for safety-critical environments, ensuring continuous and safe operation under extreme conditions.

Applications for Strength Weld and Roller Expansion in Air-Cooled Heat Exchangers

-

Offshore and Petrochemical Applications:

- Explain the high-pressure, high-temperature environments common in offshore oil rigs and petrochemical plants, where leaks or system failure could result in significant hazards.

- Discuss how air-cooled heat exchangers with Strength Weld and Roller Expansion are ideal for these challenging conditions, providing added reliability and peace of mind.

-

Power Generation Facilities:

- Describe how air-cooled heat exchangers are used in power plants to handle large volumes of heat transfer under continuous operation.

- Explain that the enhanced durability and leak resistance offered by Strength Weld and Roller Expansion make these exchangers reliable for power generation, where consistent performance is essential.

-

High-Vibration Systems:

- Describe situations where air-cooled heat exchangers are exposed to constant vibration, such as in industrial engines or transport systems.

- Explain that the mechanical stability from Roller Expansion and Strength Weld prevents loosening, making them ideal for high-vibration applications.

Why Choose HES Thailand for Air-Cooled Heat Exchanger Welding

(Strength Weld)

- Highlight HES Thailand’s technical expertise and commitment to quality, with experienced technicians specializing in tube-end welding for complex applications.

- Mention HES Thailand’s use of advanced welding equipment and precision tools for executing Strength Weld and Roller Expansion to exact specifications.

- Discuss the importance of compliance with international standards like ASME and certifications that underscore HES Thailand’s commitment to quality and safety.

- Describe the company’s dedication to customized solutions, offering specialized welding services tailored to meet the unique needs of each client’s application.

FAQs About Strength Weld, Roller Expansion, and Tube-End Welding

-

What is Strength Weld, and how does it work in air-cooled heat exchangers?

- Answer: Provide a brief description of Strength Weld and its benefits for air-cooled heat exchangers.

-

What is the purpose of Roller Expansion in tube-end welding?

- Answer: Explain Roller Expansion and its role in stabilizing the tube-end joint.

-

Why is it important to combine Strength Weld and Roller Expansion?

- Answer: Emphasize the advantages of combining both methods for enhanced durability and leak prevention.

-

Which industries benefit most from these specialized welding techniques?

- Answer: Mention industries like petrochemicals, power generation, and offshore applications.

Conclusion: Choosing HES Thailand for Quality, Reliability, and Safety

- Summarize the benefits of Strength Weld and Roller Expansion, emphasizing their role in creating robust, reliable air-cooled heat exchangers for demanding applications.

- Reiterate HES Thailand’s commitment to quality, safety, and customer satisfaction, offering advanced welding capabilities backed by an experienced team.

- Invite potential clients to contact HES Thailand for more information on tube-end welding solutions and how these methods can enhance their heat exchanger’s performance.

If you need more information or would like to include this method in your products, we are here and ready to help