Steps to select the right heat exchanger.

If you are a young engineer with no experience with heat exchangers and you are assigned to buy heat exchangers, this guide will teach you how to start, what factors and parameters to consider, and how to select the right type of heat exchanger and the right manufacturer., understanding the steps to select the right one is the most important, go to the class!

1.Study the Requirements and

Before designing your heat exchanger, it is essential to understand the specific requirements of your process. This includes:

- Process: Understand the overall process in which the heat exchanger will be integrated.

- Flow Rate: Determine the volume of fluid that will pass through the heat exchanger.

- Temperature: Identify the inlet and outlet temperatures of both fluids.

- Fluid Properties: Consider the viscosity, density, and thermal conductivity of the fluids

- Pressure Drop: Ensure the pressure drop is within acceptable limits for both the shell and tube sides.

- Size Limitation: Take into account the available space for installation to ensure the heat exchanger fits properly.

2.Design for Heat Transfer and Mechanical calculations

Process for choosing the appropriate heat exchanger, Using advanced software tools, we ensure that the design meets all performance and safety criteria:

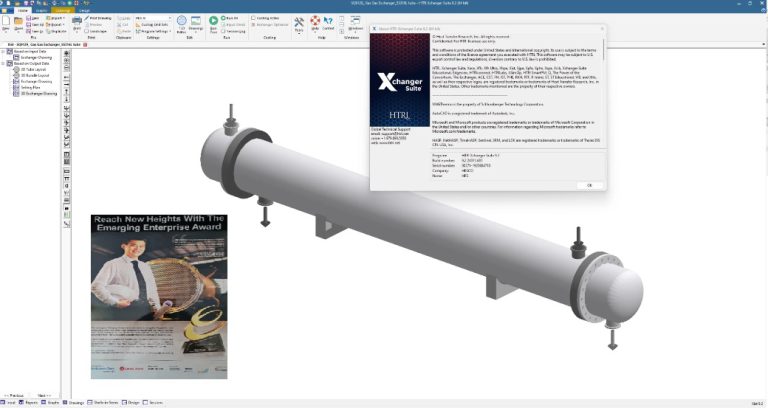

- Heat Transfer (HTRI): Utilize HTRI software to optimize the heat transfer efficiency and ensure the design meets the thermal requirements.

- Mechanical Design (PVElite): Employ PVElite for mechanical design, ensuring the heat exchanger can withstand operational pressures and temperatures.

- FEA Cyclic Analysis (Ansys): Use Ansys for Finite Element Analysis to evaluate the cyclic stresses and ensure the mechanical integrity over the lifespan of the heat exchanger.

3. Select the type of Heat Exchangers:

There is no single best type of heat exchanger; each type has its pros and cons depending on the process, size, and budget. We can suggest the type you should consider based on your specific requirements.

4. Submit Technical Design for Client Review

Once the initial design is complete, we submit all technical details to the client for review and approval. This includes detailed specifications, drawings, and calculations to ensure all requirements are met.

5. Budgetary Stage Steps to select the right heat exchanger

In this stage, we detail the budget, considering all aspects:

- Pressure Parts: All pressure-containing components are evaluated.

- Inlet and Outlet Nozzles: All sizes and ratings (class) of nozzles are specified to match the client’s system.

6. Review and Redesign

After the initial budgetary review, we work closely with the client to address any comments and redesign aspects as needed to meet all customer specifications and requirements.

7.Resubmit for Budgetary Approval

The revised design and budget are resubmitted for client approval, ensuring all changes have been incorporated and the design meets all specifications.

8.Bidding Stage

With the approved design and budget, the project moves to the bidding stage, where we finalize all commercial and technical details with the client. Steps to select the right heat exchanger

9.Kick-off Meeting

Upon winning the bid, we hold a kick-off meeting to confirm all specifications and requirements with the client. This is the transition point where the project is handed over to our project team.

10.Detailed Engineering Design

The project manager oversees the detailed engineering phase, which includes:

- General Arrangement (GA) Drawing: Creating detailed drawings for client approval.

- HTRI Report: Finalizing the heat transfer report.

- Mechanical Calculation: Completing mechanical calculations. After client approval, we proceed to create fabrication drawings.

11.Submit ITP and Welding Certifications

We submit the Inspection Test Plan (ITP), Welding Procedure Specifications (WPS), Procedure Qualification Records (PQR), and all relevant welding certifications for client review and approval.

12.Procurement of Materials

Following approval of the drawings, we procure all necessary materials, ensuring they meet the specified requirements.

13.Material Inspection

Our QA/QC department inspects all received materials to ensure they meet specifications and are free from defects.

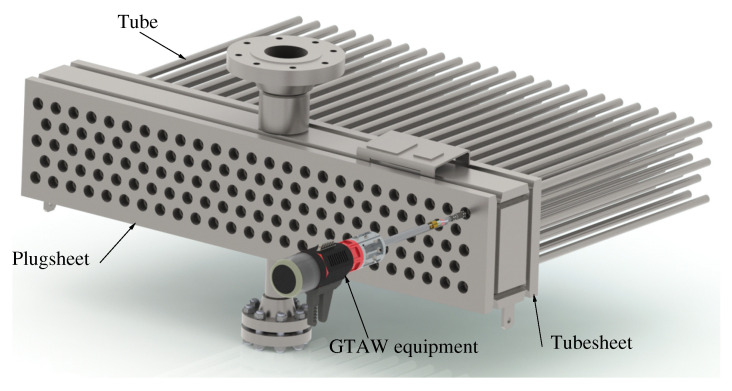

14.Start Fabrication

Fabrication begins in accordance with our standards, including ASME and ISO 9001. Our experienced team ensures each step of the process meets the highest quality standards.

15.Testing and Inspection

Before delivery, we conduct comprehensive tests to ensure the heat exchanger meets all specifications:

- Hydrostatic Test: Checking for leaks under pressure.

- Visual Check: Inspecting for any visual defects.

- Dimensional Verification: Ensuring all dimensions are correct, supported by detailed reports.

16.Delivery to Customer

After passing all tests, the shell and tube heat exchanger is carefully packaged and delivered to the customer, ready for installation and operation.

17.Strategy for identifying the best heat exchanger

Tips: How to select the right manufacturer:

Procedure for selecting the appropriate heat exchanger, Choosing the right vendor for manufacturing your heat exchanger is a critical decision that impacts the performance, reliability, and longevity of your equipment. These 9 Points You Need to Consider When Selecting the Manufacturer..

- Research Potential Vendors

- Industry Experience: Look for vendors with extensive experience in manufacturing the type of heat exchanger you need.

- Reputation and Reviews: Check customer reviews, testimonials, and case studies to gauge the vendor’s reliability and customer satisfaction.

- Evaluate Product Quality

- Certifications and Standards: Ensure the vendor complies with industry standards and holds relevant certifications (e.g., ASME, ISO).

- Materials and Components: Inquire about the materials used and the quality of components to ensure they meet your specifications.

- Assess Manufacturing Capabilities

- Technology and Equipment: Check if the vendor uses advanced manufacturing technologies and modern equipment.

- Production Capacity: Ensure the vendor can meet your production timelines and volume requirements.

- Request Detailed Proposals

- Quotation and Cost Breakdown: Get detailed quotes that include all costs (materials, labor, shipping, etc.).

- Delivery Timelines: Assess the vendor’s ability to deliver within your required timeframe.

- After-Sales Support: Consider the availability of technical support, warranty, and maintenance services.

- Pathway to selecting the most suitable heat exchanger

- Cost vs. Value: Compare quotes not just on price but on the overall value offered, including quality, service, and support.

- References and Case Studies: Request references from past clients and review case studies of similar projects.

- Visit Manufacturing Facilities

- On-Site Inspection: If possible, visit the vendor’s manufacturing facilities to inspect their processes, quality control measures, and workforce expertise.

- Check Financial Stability

- Financial Health: Evaluate the financial stability of the vendor to ensure they can sustain long-term projects and provide ongoing support.

- Negotiate Terms and Finalize Agreement

- Contract Review: Carefully review the contract terms, including payment schedules, delivery terms, and warranty conditions.

- Flexibility and Communication: Ensure the vendor is flexible and communicates effectively throughout the process.

- Establish a Partnership

- Long-Term Relationship: Consider building a long-term partnership with the vendor for future projects and continuous improvement.

Conclusion

By following these detailed steps, we ensure that our shell and tube heat exchangers not only meet but exceed client expectations. From initial requirements study to final delivery, each stage is meticulously managed to guarantee optimal performance, reliability, and customer satisfaction. Our commitment to quality and precision makes us a trusted partner in providing efficient heat transfer solutions for various industrial applications.