What is an ASME U Stamp?

The ASME U Stamp certification is a globally recognized mark of quality, issued by the American Society of Mechanical Engineers (ASME). It ensures that a pressure vessel or heat exchanger complies with the ASME Boiler and Pressure Vessel Code (BPVC). This certification specifically applies to Section VIII, Division 1, which governs the design, fabrication, inspection, and testing of pressure vessels used in industrial processes.

When a heat exchanger or pressure vessel is ASME U Stamp certified, it signifies that the equipment has been designed and manufactured to meet rigorous safety, quality, and reliability standards. This certification is essential in industries where pressure-containing equipment is critical to operations and safety.

The U Stamp is recognized and often required in industries like oil and gas, chemical processing, power generation, pharmaceuticals, and food and beverage manufacturing.

Applications of ASME U Stamp Heat Exchangers

The ASME U Stamp certification is mandatory or highly recommended in industries where high-pressure equipment and heat transfer systems play a vital role in operations. Some typical applications include:

- Oil and Gas Industry:

- Used in refineries for crude oil processing.

- Essential for heat transfer in offshore platforms and petrochemical plants.

- Commonly used in equipment like reboilers, condensers, and coolers for handling hazardous materials under pressure.

- Chemical and Petrochemical Plants:

- Ideal for processes involving corrosive fluids and high-temperature operations.

- Ensures compliance with industry safety standards for equipment like reactors, distillation columns, and heat recovery systems.

- Power Generation:

- Crucial in thermal power plants, nuclear plants, and renewable energy systems where heat exchangers handle extreme conditions.

- Examples include boilers, steam condensers, and feedwater heaters.

- Pharmaceuticals and Food Processing:

- Used in sterilizers, pasteurizers, and systems requiring hygienic processes.

- Ensures safety and efficiency in pressure-related applications.

- Marine and Aerospace Applications:

- Ensures safety in harsh operating environments like marine vessels and aircraft systems.

Why Choose ASME U Stamp Heat Exchangers?

Having an ASME U Stamp heat exchanger provides numerous benefits, particularly when dealing with high-pressure, high-temperature applications. Here are the advantages:

- Global Certification for Safety and Quality:

- The ASME U Stamp is recognized worldwide as a mark of high-quality engineering and manufacturing.

- Ensures compliance with international safety standards, making it easier to export equipment globally.

- Compliance with Legal Requirements:

- Many countries and industries require ASME certification to meet local regulations and ensure workplace safety.

- Improved Customer Confidence:

- Customers are assured that the equipment is designed and tested for reliable performance under demanding conditions.

- Minimized Risk of Equipment Failure:

- Manufacturing under ASME standards ensures rigorous testing, reducing risks associated with leaks, ruptures, or malfunctions.

- Better Marketability:

- Having ASME U Stamp-certified heat exchangers increases market value and allows manufacturers to tap into a broader range of industries and international markets.

- Long-Term Cost Savings:

- While the initial investment in an ASME U Stamp heat exchanger may be higher, the durability, safety, and efficiency lead to reduced maintenance costs and downtime.

- Adaptability Across Industries:

- With U Stamp certification, your heat exchanger can serve multiple industries, enhancing its versatility

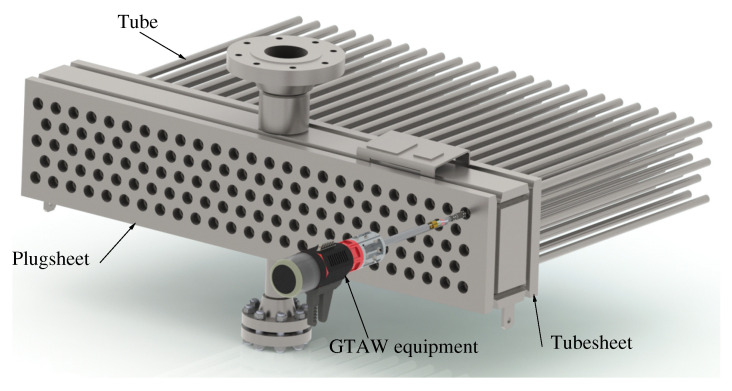

Advantages of Working with an ASME U Stamp Heat Exchanger Manufacturer

If you’re searching for an ASME U Stamp-certified heat exchanger manufacturer, partnering with the right company ensures that your equipment is built to industry-leading standards. Manufacturers with the ASME U Stamp designation provide:

- Comprehensive Engineering Support:

- Expertise in designing and fabricating pressure vessels tailored to meet the unique requirements of different industries.

- Inspection and Testing Services:

- Products undergo third-party inspections and stringent hydrostatic pressure testing to ensure compliance.

- Documentation and Certification:

- Includes all necessary compliance certificates, drawings, and inspection reports, simplifying project handovers.

We at HES are certified and verified with ASME U Stamp (U1, U2) and R Stamp, ensuring the highest quality and effective project management control. For inquiries, please contact K. Jimmy at +66 983 282 941 (based in Thailand).

more information:

https://www.facebook.com/profile.php?id=61553173482505